IMPORTANCE OF EPOXY FLOORING IN LEATHER INDUSTRY

INTRODUCTION

In the leather industry, where high standards of

cleanliness, durability, and operational efficiency are crucial, the choice of

flooring plays a significant role in maintaining an optimal working

environment. Epoxy flooring has emerged as a critical component in meeting

these demands, offering a range of benefits tailored to the unique needs of

leather manufacturing and processing facilities.

HOW INDUSTRIAL EPOXY FLOORING ACTS AS AN

PERFECT SOLUTION FOR LEATHER INDUSTRY ?

Industrial epoxy flooring is often an excellent choice

for the leather industry due to several key advantages that align with the

needs of this sector:

v Durability

Leather production environments can be harsh,

involving heavy machinery and frequent foot traffic. Leather industry epoxy floor

coating is extremely durable and can withstand heavy loads without cracking or

showing signs of wear, making it ideal for such demanding conditions.

v Chemical

Resistance

The leather industry floors involves various chemicals

and substances, including dyes, oils, and acids. Epoxy floors are resistant to

these chemicals, preventing damage and making cleanup easier, which helps

maintain a safe and clean working environment.

v Ease

of Maintenance

Epoxy floors are non-porous and seamless, meaning they

don’t trap dirt, dust, or bacteria. This makes them easy to clean and sanitize,

which is crucial in preventing contamination and ensuring hygiene in the

production area.

v Slip

Resistance

The safety of workers is a top priority. Leather

industry flooring can be modified with anti-slip additives, reducing the risk

of slips and falls, which is particularly important in environments where

spills or wet conditions may occur.

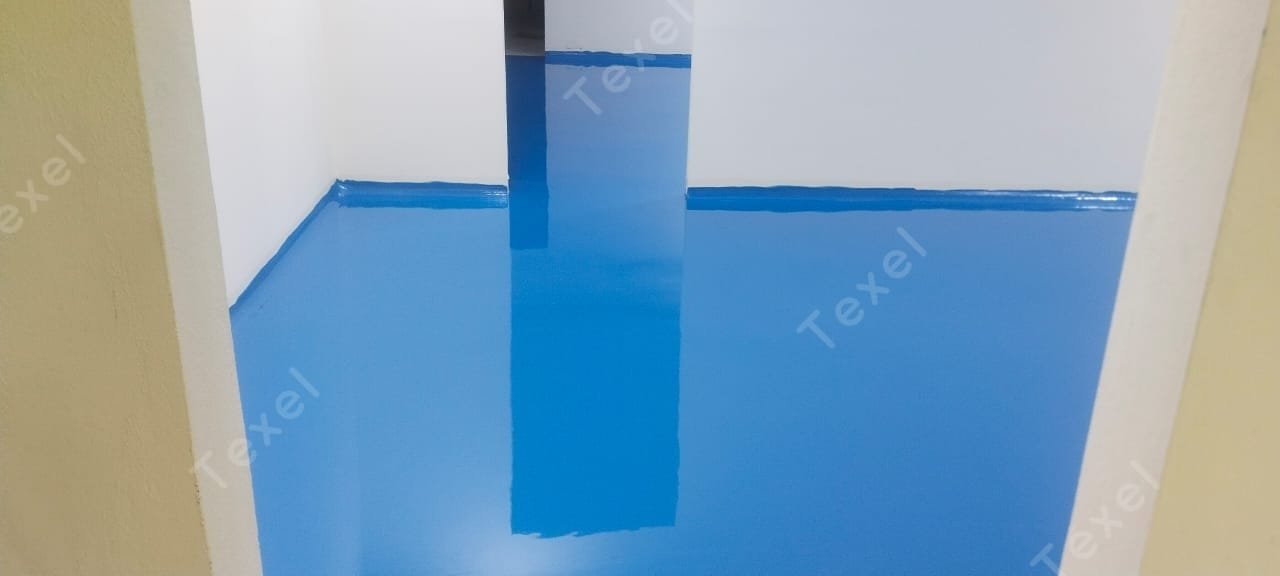

v Aesthetic

Appeal

Leather industry flooring with epoxy can be customized

with different colors and finishes, allowing for a professional appearance that

enhances the overall look of the facility. This can also be useful for designating

different areas or creating a more organized workspace.

v Temperature

Resistance

In some leather processing methods, heat can be a

factor. Floors with epoxy coating are generally resistant to high temperatures,

making them suitable for environments where heat exposure is a concern.

v Long

Lifespan

Once installed, industrial epoxy flooring can last

many years with minimal maintenance. This long lifespan is cost-effective in

the long run and reduces the need for frequent repairs or replacements.

v Installation

Efficiency

Epoxy floor coatings can be applied relatively

quickly, minimizing downtime and disruption to production schedules. This

efficiency is advantageous for maintaining operational flow in busy leather

production facilities.

v Enhanced

Hygiene and Sanitation

Epoxy formulations on industrial floors prevents the

accumulation of dust, dirt, and other contaminants, which is crucial for

maintaining high hygiene standards in the leather industry.

v Environmental

Benefits

Modern epoxy formulations can be designed with low

volatile organic compounds (VOCs), making them more environmentally friendly.

CONCLUSION

Epoxy flooring has proven to be an indispensable asset

in the leather industry, offering a multitude of benefits that address the

specific challenges faced by leather manufacturing and processing facilities.

Its remarkable durability, resistance to harsh chemicals, and ease of

maintenance make it an ideal choice for environments where exposure to dyes,

acids, and heavy machinery is routine.